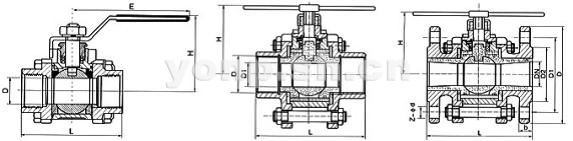

三片式锻钢浮动高压球阀

别名:Q41F高压法兰球阀

三片式锻钢浮动高压球阀

产品特点

1、采用板簧预载的可动金属阀结构,密封力设计合理,启闭灵活,密封可靠。

2、根据用户的需要,可设计成适用于含阀体颗粒、料将等介质的结构戒耐较高温度的结构。

3、采用下装式阀焊,设置倒密封结构,能确保填料处可靠密封。

三片式锻钢浮动高压球阀

主要外形尺寸和连接尺寸

| 公称通径 | 尺寸(mm) | |||

| L | H | D | D1 | |

| 10 | 90 | 76 | 32 | 3/8 |

| 15 | 90 | 76 | 32 | 1/2 |

| 20 | 100 | 81 | 38 | 3/4 |

| 25 | 115 | 92 | 45 | 1 |

| 32 | 130 | 114 | 55 | 11/4 |

| 40 | 150 | 125 | 65 | 11/2 |

| 50 | 170 | 144 | 75 | 2 |

注:对焊和承插式结构长度与内螺纹式长度相同

两边加长锻钢球阀

两边加长锻钢球阀

制造标准

1, 设计和制造符合BS5351 MSS SP-118,

2, 连接方式符合:

1) 承插焊接符合ANSI B16.11, JB/T1751

2) 螺杆两端符合ANSI B1.20.1, JB/T7306;

3) 对焊连接符合ANSI B16.25, JB/T12224

4) 两端法兰符合ANSI B16.5, JB79

3, 测试和检验符合: API598; GB/T13927, JB/T9092

材质明细表

| 序号 | 零件名称 | 碳钢 | 不锈钢 | ||

| 1 | 阀体 | A105 | F304 | F316 | F316L |

| 2 | 球 | F304 | F316 | F316L | |

| 3 | 阀杆 | F304 | F316 | F316L | |

| 4 | 密封圈 | PTFE, RPTFE, 尼龙 | |||

| 5 | 垫片 | O型圈, PTFE, 石墨 | |||

| 6 | 填料 | PTFE, 石墨 | |||

| 7 | 止推垫片 | PTFE | |||

| 8 | 定位片 | A283D, 不锈钢 | |||

| 9 | 手柄 | A283D, 不锈钢 | |||

| 10 | 螺母 | T304 | |||

| 11 | 定位销 | T304 | |||

| 12 | 螺母 | A194-2H | A194-8 | ||

| 13 | 螺栓 | A193-B7 | A193-B8 | ||

尺寸(MM)和重量(KG)? ???800Lb~1500LB

| RB | FB | L | d | B | NPT | SW | L1 | H | W | 重量 KG | ||||

| RB | FB | RB | FB | RB | FB | RB | FB | |||||||

| 3/8x1/4 | 1/4 | 92 | 9.5 | 17.2 | 13.8 | 3/8 | 1/4 | 17.6 | 14.2 | 9.6 | 9.6 | 53 | 130 | 3.5 |

| 1/2x3/8 | 3/8 | 92 | 9.5 | 21.3 | 17.2 | 1/2 | 3/8 | 21.8 | 17.6 | 9.6 | 9.6 | 53 | 130 | 3.5 |

| 3/4x1/2 | 1/2 | 92 | 13 | 26.9 | 21.3 | 3/4 | 1/2 | 27.1 | 21.8 | 12.7 | 12.7 | 56 | 130 | 3.5 |

| 1x3/4 | 3/4 | 111 | 17 | 33.7 | 26.9 | 1 | 3/4 | 33.8 | 27.1 | 12.7 | 12.7 | 70 | 160 | 4.8 |

| 11/4x1 | 1 | 127 | 23 | 42.4 | 33.7 | 11/4 | 1 | 42.6 | 33.8 | 12.7 | 12.7 | 80 | 220 | 7.5 |

| 11/2x11/4 | 11/4 | 140 | 30 | 48.3 | 42.4 | 11/2 | 11/4 | 48.7 | 42.6 | 12.7 | 12.7 | 90 | 250 | 13.5 |

| 2x11/2 | 11/2 | 152 | 38 | 60.3 | 48.3 | 2 | 11/2 | 61.2 | 48.7 | 15.9 | 15.9 | 100 | 250 | 15.8 |

| 21/2x2 | 2 | 178 | 48 | 76.1 | 60.3 | 21/2 | 2 | 74.1 | 61.2 | 15.9 | 15.9 | 110 | 290 | 19.2 |